For laser cutting job shops, staying competitive is essential to running a profitable business. But how do you measure that? How do you know where you sit compared with other job shops in your area, with a similar laser power, or with a similar service offering?

One way to understand your position in the marketplace is to look at your win/loss ratio. The Tempus Tools leadership team, which has more than 100 years of combined experience – extending from the job shop floor to the formation of entire laser cutting enterprises – has found that a typical win/loss ratio is about 30-40%.

This means, for every 100 jobs you quote for, you win 30-40 of them. But it’s important to consider not just how many jobs you win, but how profitable they were to your business. Here are two common mistakes we see:

- Your win/loss ratio is under 30%, so you aren’t winning enough jobs. This can often be because your pricing is too expensive, and is not competitive with other companies offering similar services.

- Your win/loss ratio is above 40%, so you’re winning a lot of jobs, but your pricing may be too cheap, and it’s becoming a lot of work for very little profit margin.

My win/loss ratio is off – what should I do?

The first thing all laser cutting businesses should consider is what they do best. This is usually what makes the most money, and achieves a long-term profitable business.

For example, you might specialise in cutting thicker materials. Your team might have good expertise in this area, can produce high quality jobs, and you have the right stock on-hand. In this case, you should look at accepting more quotes that involve thicker materials.

Other factors to look out for include:

- Material pricing. This is a significant cost for any laser cutting business, so it’s crucial for any job shop to maintain the correct margin.

- Hourly rate. This should be monitored all the time, and a long-term strategy should be put in place. It can sometimes hurt the business to drop your rate too much just to win a particular job.

- I’m losing too many small jobs. This could mean your setup costs are too high, making you less competitive with other job shops.

- I’m losing too many large jobs. This could mean you haven’t considered the discount others are providing for larger work, due to economies of scale.

- I’ve seen what other companies are offering, and wonder if I should lower my price to that level too, so I can win the work? This strategy is not advisable, because the other company might be cutting corners on quality, or might have an inaccurate quote to begin with. Nobody wins with a race to the bottom on price – that only favours those with poor quality and no backup. The metal cutting industry as a whole has a responsibility to maintain high standards of quality and service, which benefits both customers and job shops.

The goal is to achieve long-term profitability, not to compromise to win a particular job.

How do I keep all these figures accurate?

One of the most effective ways to win and retain business is to provide accurate and consistent quotes. But job shops use all sorts of methods, from manual spreadsheets to home-grown software, and these don’t always arrive at the right price, which can result in unexpected loss of jobs.

Tempus Tools conducted its own research and asked more than 250 users about their previous quoting methods. 54% of users in the survey admitted they had inaccurate quoting methods, which is indicative of the industry more broadly.

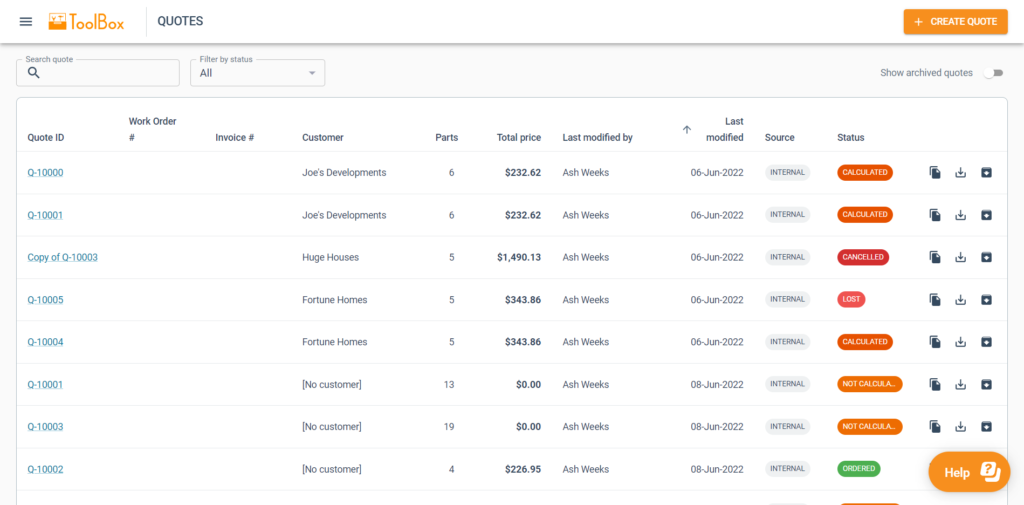

One solution is ToolBox, by Tempus Tools, a multi-functional laser cutting quoting software provided using a SaaS (Software as a Service) model, so laser job shops can achieve accurate and consistent pricing every time.

ToolBox is rules-based, so users can set rules for material cost, hourly rates, secondary processes, and other parameters required to create accurate quotes.

ToolBox has been designed so that anyone can use the program, with no CAD or CAM training or software required. Job shops such as Red Horizon Engineering have found this to be a great benefit, with owner Steve Geroski commenting, “ToolBox has been one of the smoothest and most intuitive programs I’ve ever used. This meant I could implement it straight away and start quoting for orders while continuing to set up other parts of the job shop.”

Frank Maat, owner of Rolleston Sheetmetal Engineering, added “I like that my laser machine operator and I can get an accurate idea of material usage, time, labour, and other relevant data for each job – and it greatly reduces the risk of human error, because ToolBox is a rules-based program.”

Hurstbourne Forge owner, Jack Swanborough, says “ToolBox is much better than anything we’ve used before, especially for larger and more complex quotes – and I like that it handles all the folding and secondary processes automatically.”

Conclusion – consistency and accuracy are key

If job shops are not running a quoting system, most of the time they are just guessing on pricing when they respond to quotes. This guesswork not only takes longer to complete, but can cause inaccuracies and inconsistencies that can lose business.

With ToolBox, users can set rules to keep pricing consistent and accurate, removing irritating customer issues when they receive two different prices for the same job.

So if you are looking to see how competitive and profitable your job shop is, take a look at your win/loss ratio, compare this with your profit and loss statement, and see where adjustments need to be made.

Our laser cutting quoting experts can help by providing seasoned advice on where minor changes can make a major difference to operations.

To learn more about ToolBox, by Tempus Tools, please click here.

Author: Bruce Thomas, Executive (Product)