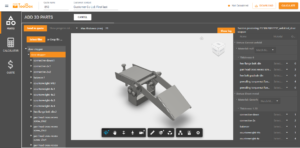

Hurstbourne Forge owner, Jack Swanborough, pictured, uses his laser cutting machine to create unique, high-quality metal homewares, gifts, and bespoke commissions for both the modern and traditional home. Team mascot Ralphy keeps an eye on the Tempus Tools ToolBox software, which is providing simple, efficient, and accurate laser cutting quoting.

Bespoke metal fabrication specialist, Hurstbourne Forge, has found an elegant and efficient solution to its varied laser cutting quoting needs for its job shop in Andover, Hampshire, in the UK.

The family-owned business, run by Jack and Lydia Swanborough produces “pretty much anything in metal – with precision and care” and specialises particularly in small-to-medium volume bespoke and batch work.

“Quoting customers for these highly specialised jobs was taking time and effort, and we knew there had to be a more efficient way. We discovered ToolBox, by Tempus Tools, and it ticked all the boxes for us. It was such an elegant solution,” said Jack, who has been in the current premises in Andover for the last 2.5 years.

“ToolBox gave us an automatic quoting system with a simple interface and a good front-end solution for self-service customers. Other solutions I looked into were needlessly complex, expensive, or both,” he said.

Hurstbourne Forge operates with a fibre laser, press brake, and a broad range of secondary processes, including welding, bending, forming, folding and ring rolling, powder coating, shotblasting, and refinishing.

“ToolBox is much better than anything we’ve used before, especially for larger and more complex quotes – and I like that it handles all the folding and secondary processes automatically. It’s ideal, because we just installed a new press brake to keep up with growing demand,” said Jack.

“We have a fairly small laser and press setup by global standards, but run a full drawing to final part service for fabrication in any material in-house, specialising in fast turnaround, one-off and weird and wonderful bespoke jobs. We have very attractive pricing for short run laser jobs that are often expensive to get done elsewhere, and ToolBox is helping streamline our quoting efficiency to further reduce our costs,” he said.

STEP-ping up with new features

Tempus Tools seeks feedback from customers and uses this to add new features and make improvements to ToolBox. The leadership team has more than 100 years of combined experience in the laser cutting industry, from hands-on, practical shop floor work, through to company management.

“One of the features we really enjoy is that we can get quick PDF quotes straight out to customers. The ability to directly translate 3D STEP files into a PDF quote is a game changer for the efficiency of our business,” said Jack.

With ToolBox, users can identify, extract, and unfold sheet-metal parts directly from 3D assemblies without a 3D software package. The flattened 2D drawings can be exported as DXF and DWG files with cut and fold lines for use in production or other systems.

Tempus Tools Director, Felipe Lechuga, says that the automatic 3D unfolding feature removes a number of previous obstacles for job shops. “3D software packages are expensive, trained operators are expensive, and finding the time to train people (if they have no prior experience) is hard too. We have designed ToolBox so job shops of any size can handle 3D files with ease, with no need for software or specialised skillsets.”

Hurstbourne Forge also utilises the ToolBox Web Store feature, so that customers can get a quick quote automatically through their own website.

“The Web Store interface is great for our small-to-medium volume batch work. It means customers can use our website as a self-service e-shop for our products, saving them time, and increasing business for us,” said Jack.

“And what further sets the Tempus Tools team apart is they are highly responsive to any questions or requests for support. I can reach out and discuss new features directly with the development team – and see them implemented – which is fantastic,” he adds.

“We’ve just added Xero integration – another highly useful feature – and our business is running at its highest level of efficiency. ToolBox has greatly contributed to this increased productivity, and I’m excited to see new features and improvements continue to be rolled out.”

To learn more about ToolBox, by Tempus Tools, please click here.

Hurstbourne Forge can be contacted on:

www.hurstbourneforge.co.uk

Ph: +44 01264 527 017

Email: info@hurstbourneforge.co.uk