Quiet achiever Frank Maat specialises in bespoke and unique metal fabrication jobs, through his business Rolleston Sheetmetal Engineering.

Based in Rolleston, New Zealand (about 25km South-West of Christchurch), Frank’s company predominantly serves the agricultural community, including its suppliers and contractors, who request anything from large silos to storage boxes, to safety handrails, and everything in between.

Frank soon realised that he was spending too much money, and waiting too long, by getting laser cutting done by a third party, so he invested in his own laser cutting machine.

“I wanted to be in control of timelines and deadlines, so I could deliver more reliably to my customers, so I purchased a brand new laser machine. But then I had a new challenge – how do I accurately quote jobs?” said Frank.

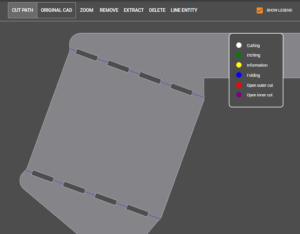

After speaking with connections in the industry, Frank received a recommendation for ToolBox, by Tempus Tools, an all-in-one laser cutting quoting software that is provided using a SaaS (Software as a Service) model.

“I’m not a technology person, so at first I was apprehensive about using a software, which I worried would be too complex. But ToolBox was very intuitive and user-friendly, and I’ve been really enjoying its features,” he said.

“I like that my laser machine operator and I can get an accurate idea of material usage, time, labour, and other relevant data for each job – and it greatly reduces the risk of human error, because ToolBox is a rules-based program.”

“Additionally, the ToolBox software is easily adjustable, which allows me to tread that fine line between being competitive and being profitable,” added Frank.

Rolleston Sheetmetal Engineering also uses secondary processes such as folding, powder coating, tapping, and galvanising, and ToolBox can include these in quotation calculations.

Tempus Tools Director, Felipe Lechuga, says it’s rewarding to help a small business like Rolleston Sheetmetal Engineering, which is focused on delivering the best customer service in the most efficient way.

“Businesses like this give us the opportunity to not only provide software that benefits the owner, but to also impart our knowledge from our own experience in laser cutting, so that they don’t have to make the same mistakes we once did,” added Felipe, who, in addition to his role at Tempus Tools, runs his own laser cutting business, Lemaco SpA, in Chile.

Outstanding support

In addition to a range of useful features, Frank has been impressed with the support offered by the Tempus Tools team.

“The support has been truly fantastic. Tempus Tools staff have helped me with calculations on my hourly rate, and every time I have a question, they are available promptly to assist me,” he said.

“It gave me confidence that the Tempus Tools leadership team all have decades of practical experience in laser cutting, both on the job shop floor, and at management level, so they know the sorts of challenges and opportunities I face with my business.”

Frank is optimistic about the future, but has humble plans for future expansion. “I’m not going to rush into growth, but I know the possibility is there, and I plan to go about it quietly. I know ToolBox will be able to grow with me, when I need it, because the same program can run more quotes and add different secondary processes as required.”

To learn more about ToolBox, by Tempus Tools, please click here.

Rolleston Sheetmetal Engineering can be contacted on:

Ph: +64 (0) 29 771 7050

Email: office@rollestonsheetmetal.nz