When you’re quoting for a laser cutting job, the major components that determine price are the material cost, the fixed and variable costs of your laser cutting system and the labour costs.

Material costs typically represent more than 55% of the part price and, of the remainder, the machine’s fixed and variable costs represent the major portion. Understanding material costs and knowledge of future trends in material costs are key factors in determining your quotation part prices.

Fluctuations in material cost are so easy to overlook. If you’re not careful, and not keeping pricing up to date, you could lose money on the job.

Material price changes

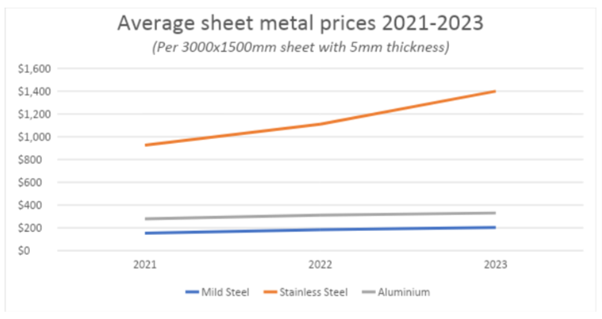

Let’s take the three most common metals for laser cutting jobs – mild steel, stainless steel, and aluminium, and see how they’ve changed over recent years. Prices can vary greatly due to geopolitical events, economic conditions, and global supply and demand.

Keeping an eye on markets and pricing changes, and updating your quoting system to reflect the newest prices will help make sure you are never in a situation where you are losing money on a job because of an inaccurate laser cutting quote.

Sheet Metal Price – raw data

For the purposes of this analysis, we will take a standard 3000x1500mm sheet with 5mm thickness. All prices are in US Dollars (USD).

| Material | Year | Cost per tonne (approx.) | Weight of sheet | Cost per sheet (approx.) |

| Mild Steel | 2023 | $700-$900 | 178kg | $154-$252 |

| 2022 | $600-$800 | $132-$234 | ||

| 2021 | $500-$700 | $110-$196 | ||

| Stainless Steel | 2023 | $2,000-$4,000 | 175kg | $800-$2,000 |

| 2022 | $1,800-$3,000 | $720-$1500 | ||

| 2021 | $1,500-$2,500 | $600-$1,250 | ||

| Aluminium | 2023 | $2,000-$2,500 | 61kg | $260-$400 |

| 2022 | $1,900-$2,200 | $247-$376 | ||

| 2021 | $1,700-$2,100 | $221-$336 |

The data above shows that for mild steel (which is used on approximately 85% of laser cutting jobs), prices have risen more than 30% from 2021-2023. Stainless Steel has seen an even bigger increase, with prices rising more than 50% during this same period. Aluminium has seen price increases of around 18% over that time period.

In some cases, the difference may not seem like a lot, but it can really add up as the volume of laser cutting jobs increases.

What if prices go down?

We haven’t seen this happen for a while, but what happens if material prices go down? Then, you have the opposite problem.

If you are still charging the higher price, but your competitors have updated their material costs, they will be winning more jobs, because their job shop estimating software allows them to offer more competitive quotes will be more competitive.

Let your quoting system keep you accurate and consistent

One way to keep material pricing data accurate is to use a rules-based laser cutting quoting software like ToolBox, by Tempus Tools, where you can set the current market pricing of materials to assist you in delivering accurate, consistent, and fast quotes, every time.

ToolBox also has a range of features – developed by professionals with decades of hands-on experience in the laser cutting industry – to make laser cutting quoting easier and quicker, so that job shops can reduce costs, save time, and win more work. Some of these features include:

- Automatic 3D unfolding, with the ability to turn 3D models into quotable 2D drawings

- Web Store, which gives job shops their own online store where customers can get 24/7 pricing and place orders

- Drawing Doctor® to fix up errors in customer drawings

- Part Library – save parts data to make repeat orders even faster

- … and many more time-saving features!

If you’d like to see how simple quoting via ToolBox is, you can start a no-obligation 14-day free trial.

Author: Bruce Thomas, Executive (Product)