Industry-specific, sales-focused quoting software means you spend less and sell more

Most laser, plasma, waterjet, oxy cutting, folding (and secondary processes) jobshops are using inefficient estimation methods, because they are not aware that industry-specific software exists.

The lack of a streamlined and inexpensive estimating procedure may be one of the biggest roadblocks for jobshop growth, because the inability to send accurate and timely quotes (at a low cost) prevents companies from selling more, increasing production, and expanding the business.

But it doesn’t have to be that difficult.

Let’s take a look at the biggest quoting problems jobshops are facing, and how an industry-specific sales-focused quoting software can boost competitiveness and foster business growth.

The problem with non-specific software

Different types of software provided by machine manufacturers, or CAM software, are excellent production-focused tools… but they are not sales software. They haven’t been specifically designed so that you, as a jobshop, can quote quickly, quote accurately, and maximise the number of quotes you win.

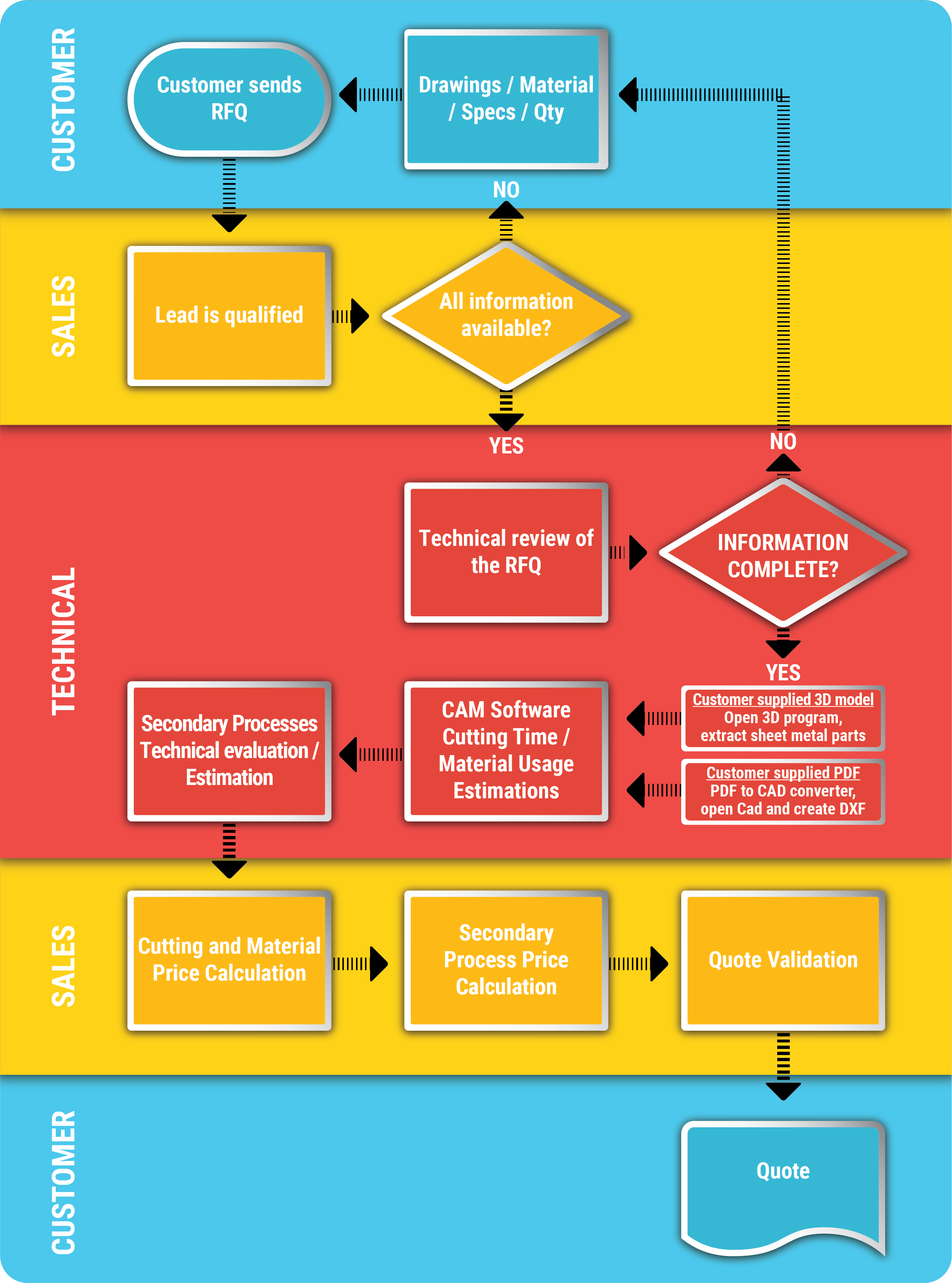

A typical estimation and quoting process using these types of software (or worse, a spreadsheet with all the information stored in one person’s head!) often encounters the following roadblocks:

- A heavy reliance on the manager or owner for quoting, because only they know the pricing policy and what discounts can be applied

- Difficulty keeping up with sheet price changes

- High risk of not bidding on larger jobs because of the complexity of quoting. This could be because of:

- Too much time needed to quote

- Shared resources (labor/software) for estimating and production

- Multiple drawings

- Multiple materials

- Multiple secondary processes

- Multiple estimation stages, which means:

- More resources are involved

- Highly skilled labor is required

- High cost of software licenses needed

- Higher error risk (multiple points of information processing and information circulation)

- Longer processing times

- Higher risk of delivering late quotes

Here’s how a typical quoting flow looks like with these systems in place:

Typically, only 30-40% of jobs quoted are won, meaning that a large portion of the estimating cost is lost, lowering the company’s competitiveness.

Inefficient estimating means that jobshops buy more CAM software licenses and employ more highly skilled labor than they really need.

Production software isn’t efficient for jobshop quoting

Laser machine manufacturers focus their software on production, because that’s what’s required to run the machines. So, when quoting is added to this software, it’s often difficult to use. You may notice:

- The software is designed to be used by experts such as designers and machine programmers

- There is no automated drawing cleaning – you’ll have to do this yourself

- 3D assemblies are processed manually on a 3D software package for 2D parts extraction

- Only output time and material usage are included – no pricing

- Most secondary processes (powder coating, tapping, mig welding and a range of others) must be estimated on a different software, spreadsheet, or done manually.

But what about ERP or CPQ systems?

Some jobshops see the inherent weaknesses in the production-focused software, and the next option is to explore Enterprise Resource Planning (ERP) or Configure Price Quote (CPQ) systems.

These systems have their advantages, but they fall short when it comes to providing quotes as a sales tool, to grow the business. This is because, with ERPs and CPQs:

- There are no standard quoting modules

- There are no industry-specific business rules

- Costly workarounds are regularly required to accommodate cutting, material, and secondary processes in quotes due to the standardized characteristics

- Quotes do not include thumbnail drawings of the parts (simple point of error detection by customers)

Laser / Plasma / Waterjet / Oxy cutting (+ Secondary processes) quoting should be done in an estimating-specific software, not on an array of production, spreadsheets and generic ERP software packages that add cost and stifle efficiency.

Where can I find industry-specific sales focused software for jobshop quoting?

You’ve come to the right place. ToolBox, by Tempus Tools, has been designed as a sales software. It is a customer-facing solution that has been designed to help jobshops sell more.

Not only is it a sales software, but ToolBox is rules-based, which enables lesser skilled customer-facing service staff to prepare and issue quotes. This means it’s not taking highly qualified CAM specialists and brake press operators away from their productive tasks to assist with quote preparation.

ToolBox has all the tools a jobshop needs to get more quotes to customers, win more jobs, and grow the business.

Remember that convoluted and long quoting flow diagram from earlier? Here’s how it could look with ToolBox:

ToolBox sounds interesting – how do I know if it’s right for my jobshop?

The best way to see if a software works for you, is to try it. If you have a laser, plasma, waterjet, or oxy cutting machine, we believe ToolBox can save you time and win you more business.

To prove this to you, we are offering a no-obligation trial where you can try ToolBox for free for the first 14 days.