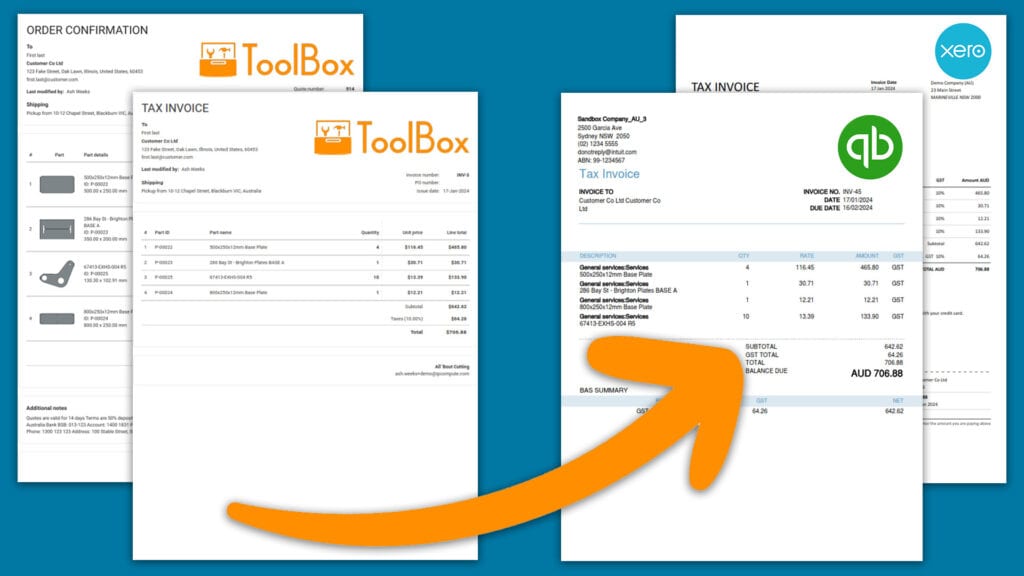

Accounting software integrations boost laser cutting quoting efficiency for SMEs

Small laser cutting and metal fabrication job shops face big challenges. With a limited number of staff on the roster, each person is performing multiple roles, from estimator, to customer service, to accountant, to production manager, and more. According to the World Bank, Small and Medium-Sized Enterprises (SMEs) “represent about 90% of businesses and more […]

How manual quoting inconsistencies can lose laser cutting jobs

The only time a laser cutting job shop is earning revenue is when that red light is on, sparks are flying, and the laser is in use. Everything else is done to support this activity, and to maximise the utilisation of the laser machine. This is one of the major reasons why using a laser […]

When spreadsheets don’t cut it: laser cutting quoting software slices through wastage

Laser cutting businesses often decide to use spreadsheets to develop and provide quotes, as a way to save money on specialised software. But does the maths stack up? In our experience, it’s actually costing more than it’s saving – and here’s why. Based on data from millions of line items quoted, Tempus Tools calculates that […]

How to use win/loss ratios to keep your laser cutting job shop competitive and profitable

For laser cutting job shops, staying competitive is essential to running a profitable business. But how do you measure that? How do you know where you sit compared with other job shops in your area, with a similar laser power, or with a similar service offering? One way to understand your position in the marketplace […]

Tips For New Laser Owners

So you’ve just bought a new laser cutting machine… what next? A laser cutting machine is a big investment. Depending on the features included, they can be north of $1 million, so you want to be gaining maximum value from your investment. But how do you know what to charge? What are your expenses vs […]

5 Features Of A Good Quoting System

Automated sheet metal quoting is based on the data present within a 3D CAD model, combined with user-inputted, non-geometric information. It cross-examines the model in order to withdraw geometric data that is applicable to sheet metal manufacturing, such as the number of bends, the thickness of the material, and the length of the cut. With […]

Types of Sheet Metal Estimating Software Available on the Market

Sheet metal estimating and quoting can be a very time-consuming task, which can play a role in determining a job shop’s profitability. Have you found it difficult to respond to a customer’s Request For Quote (RFQ) quickly? Do you want to find a solution to minimise the necessary administrative steps when it comes to estimating […]

Is Your Brake Press Breaking The Budget? Save Costs And Operator Time With Front-End Quoting

Most laser job shop owners will agree that a brake press operator is one of the most expensive people in the jobshop – and is often the hardest to find. With bending being an essential component of most job shops’ processes, having the right brake press (and operator) is a must. So, if you’ve finally […]

Inefficient quoting is holding back jobshop competitiveness

Industry-specific, sales-focused quoting software means you spend less and sell more Most laser, plasma, waterjet, oxy cutting, folding (and secondary processes) jobshops are using inefficient estimation methods, because they are not aware that industry-specific software exists. The lack of a streamlined and inexpensive estimating procedure may be one of the biggest roadblocks for jobshop growth, […]

Getting around the spike in steel prices

Steel prices have been on a steady climb from August of last year, going from an average price of $473 USD to the current $1,770 per ton of HR steel in North America. Given the last major high even remotely close to this in the past decade was $915 per ton in July 2018, fabricators […]